Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp+86 18621680941

The landscape of packaging materials is evolving. Among these advancements, Pbl/Rpbl Laminate Film stands out. Its unique properties make it valuable in various industries. These films are designed for durability and usability. They provide excellent barrier protection, enhancing product shelf life.

In recent years, the demand for Pbl/Rpbl Laminate Film has surged. More brands are adopting this film for sustainable packaging solutions. This shift is driven by consumer preferences for eco-friendly products. However, challenges remain. Manufacturing processes can be complex, requiring constant innovation.

Various applications showcase the versatility of Pbl/Rpbl Laminate Film. From food packaging to electronics, its potential is remarkable. But companies must remain vigilant. They need to address environmental impacts effectively. Balancing functionality and sustainability is crucial for future growth.

PBL (Polybutylene) and RPBL (Reinforced Polybutylene) laminate films have emerged as significant players in various industries. These materials are noted for their impressive mechanical properties, including high tensile strength and durability. According to a recent report, the global market for PBL films is projected to grow by 5.4% annually, reaching approximately $1.2 billion by 2026.

The applications of PBL and RPBL laminate films are diverse. They are utilized in construction, automotive, and packaging sectors. The films' resistance to chemicals and moisture makes them ideal for protective coatings and barriers. In the automotive industry, they help in reducing vehicle weight while maintaining strength. However, challenges lie in optimizing production processes to minimize waste, as more than 30% of material can be lost during manufacturing.

Innovative technologies are crucial to enhancing the properties of these films. Advances in polymer science are aimed at improving their thermal stability and flexibility. While these developments show promise, ensuring environmentally sustainable production remains a concern. The industry must reflect on the balance between performance and ecological impact, as consumer expectations continue to evolve.

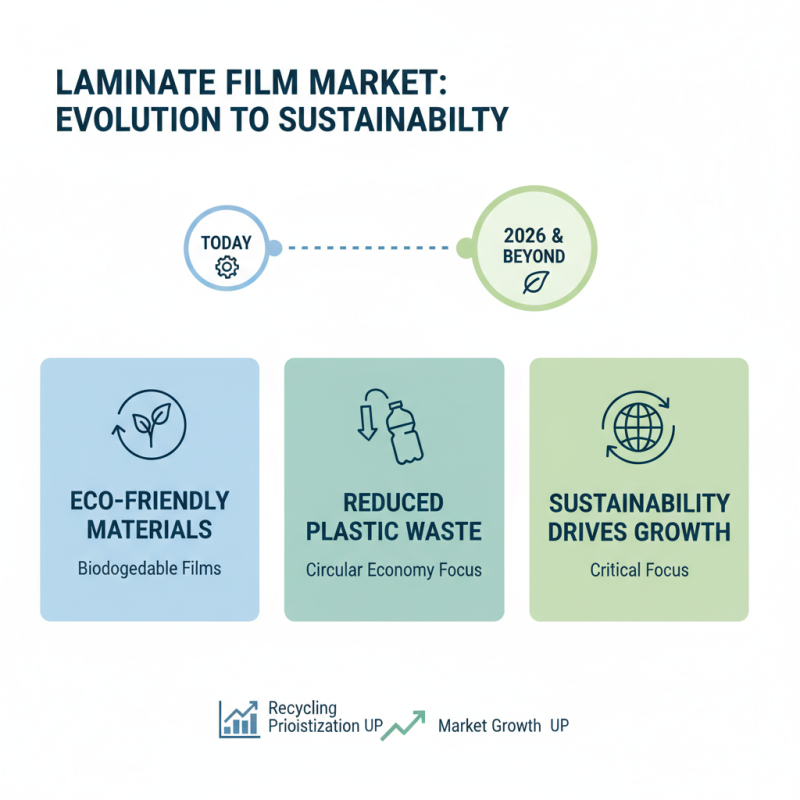

The laminate film market is evolving rapidly. In 2026, sustainability will be a critical focus. Eco-friendly materials are rising in prominence. Biodegradable films are capturing attention. Companies are increasingly prioritizing recycling. This push aims to reduce plastic waste.

Innovative designs are also gaining traction. Colorful patterns and textures enhance product appeal. Personalization options are becoming more common. Brands want their products to stand out on shelves. Unique finishes can attract more consumers. However, balancing aesthetics with functionality remains a challenge. Many products still lack durability.

Another trend includes technological integration. Smart laminates can provide interactive features. Users desire convenience and engagement. Yet, finding the right technology can be difficult. Balancing cost and quality is essential. These trends reflect a transforming landscape in the laminate film industry. The journey is filled with opportunities and challenges.

The evolution of PBL and RPBL laminate films is transforming industries. These films are now being utilized in packaging, electronics, and automotive sectors. Their lightweight nature reduces overall product weight, enhancing efficiency. In packaging, they provide better barrier properties, keeping products fresher for longer. This innovation helps in reducing food waste, but challenges in recyclability persist.

In electronics, PBL films are used in flexible displays and solar cells. Their flexibility allows for new designs and applications. While this fosters creativity, manufacturers face difficulties in ensuring durability. The automotive industry benefits too, with these films contributing to vehicle weight reduction and fuel efficiency. However, there are concerns about their environmental impact. The balance between innovation and sustainability needs careful consideration.

Adopting these films can lead to improved performance, but issues remain unresolved. Companies must continuously innovate while addressing the challenges that come with these advanced materials. The road ahead is filled with opportunities, yet the quest for sustainable solutions is ongoing.

The laminate film industry faces increasing pressure to adopt sustainable practices. Environmental awareness is growing. Consumers care deeply about how products affect our planet. As production ramps up, the industry must find ways to reduce its ecological footprint.

One significant challenge lies in sourcing raw materials. Many laminate films rely on fossil fuels, which are finite. Switching to renewable resources can be a game changer. Biodegradable options are emerging. However, they often cost more and may not perform as well. It's essential to find a balance between cost and sustainability.

**Tip:** Consider using recyclable materials in your production process. This can enhance your product's appeal.

Furthermore, the production process itself can be wasteful. Many manufacturers still use outdated methods that generate excess waste. Implementing more efficient techniques can help mitigate this issue. Automation and smart technology could play a role in producing less waste while preserving quality.

**Tip:** Regularly assess your production methods. Look for opportunities to improve efficiency.

By rethinking both materials and processes, the laminate film industry has the potential to become more sustainable. It's a journey filled with trial and error, but each step can lead to a more responsible future. The quest for greener practices is ongoing and requires commitment from all stakeholders.

The future of PBL and RPBL laminate films holds exciting prospects yet presents significant challenges. These materials find uses in various sectors, from packaging to electronics. As industries push for eco-friendly solutions, the demand for sustainable laminate films grows. Innovations like biodegradable components may emerge, but compatibility with existing processes remains a concern.

On the challenge front, achieving durability while maintaining environmental standards is tough. There is ongoing research to balance performance and sustainability. Companies may struggle with the cost of developing new materials. This can slow down the adoption of advanced PBL and RPBL films in the market. Additionally, the recycling process for these films is not fully established, which raises questions about end-of-life solutions.

Industry professionals must reflect on these issues. Engaging with environmental scientists could spark new ideas. There are lessons to learn from past failures—understanding what didn't work can guide future innovations. As the landscape changes, adaptability will be key. Embracing challenges may lead to groundbreaking advancements in laminate film technology.