Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp+86 18621680941

In the world of architectural finishes and design elements, the selection of materials plays a pivotal role in the overall aesthetic and functionality of a project. Coated Aluminum Laminate Film has emerged as a preferred choice among architects and designers due to its versatility and durability. Industry expert Dr. Emily Johnson, a leading specialist in composite materials, states, “The right Coated Aluminum Laminate Film not only enhances the visual appeal of a space but also offers unparalleled protection against environmental factors.”

Choosing the best Coated Aluminum Laminate Film for your project involves understanding the various options available and how they align with your design objectives. Factors such as texture, color, and finish can significantly impact the outcome of a project. Furthermore, the right selection can contribute to sustainability efforts and ensure longevity, making it an essential consideration for anyone in the design and construction field.

As we delve into the process of selecting the ideal Coated Aluminum Laminate Film, it is crucial to weigh the performance characteristics alongside the aesthetic demands of your specific application. By doing so, you not only achieve the desired look but also enhance the overall durability and functionality of your space.

Coated aluminum laminate film is a versatile material often used in various applications due to its unique properties. Comprised of aluminum layers coated with a protective film, this laminate offers excellent durability while maintaining a lightweight profile. It is resistant to corrosion, UV radiation, and scratches, making it suitable for both outdoor and indoor use. This material is widely utilized in architectural facades, signage, and interior design elements, where aesthetics and performance are equally essential.

The applications of coated aluminum laminate film extend beyond just visual appeal. In the construction industry, it is used for cladding systems, providing not only insulation but also an appealing finish that can withstand harsh weather conditions. Additionally, its reflective properties contribute to energy efficiency in buildings. In retail and exhibition spaces, the laminates can create eye-catching displays that enhance branding while providing the durability needed to withstand high foot traffic. Overall, understanding the characteristics and applications of coated aluminum laminate film is crucial for selecting the right material for your project.

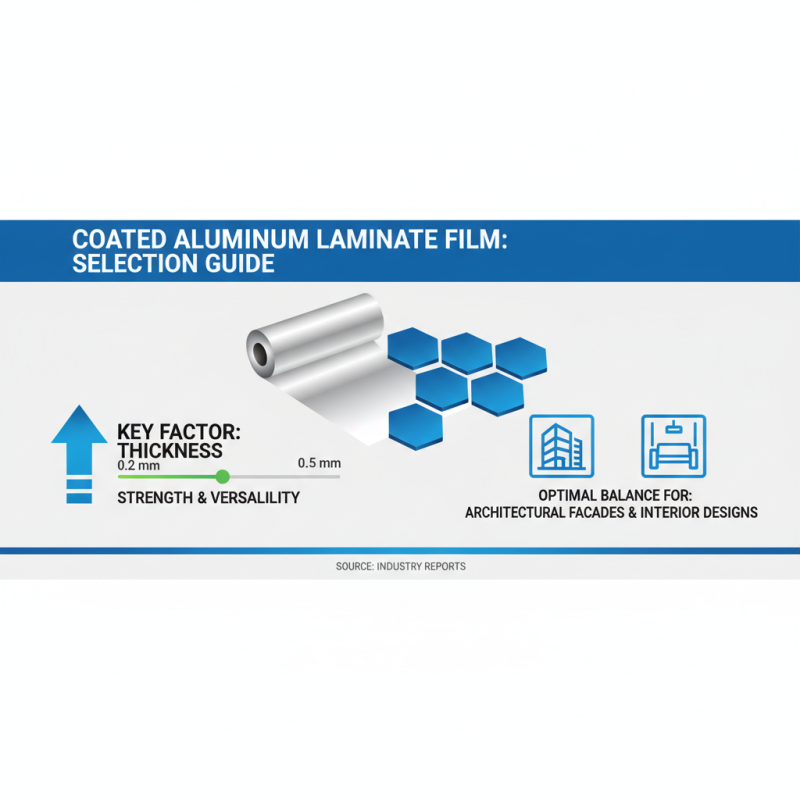

When selecting coated aluminum laminate film for your project, several key factors must be taken into account to ensure optimal performance and durability. One of the primary considerations is the film’s thickness, which can greatly influence its strength and versatility. According to industry reports, films with a thickness ranging from 0.2 to 0.5 mm provide a balance between flexibility and durability, making them suitable for a wide range of applications, from architectural facades to interior designs.

Another critical factor is the coating type used on the aluminum laminate. Different coatings can offer various levels of resistance to environmental factors such as UV rays, moisture, and corrosion. For instance, polyvinylidene fluoride (PVDF) coatings are known for their exceptional weather resistance and longevity, with some studies indicating a lifespan exceeding 20 years under normal conditions. Additionally, aesthetic preferences, such as color and finish, are also important, as these attributes can impact the overall appearance and integration of the film in design projects. By carefully evaluating these factors—thickness, coating type, and aesthetic compatibility—designers can select the most suitable coated aluminum laminate film to achieve their vision.

When selecting the best coated aluminum laminate film for your project, it's essential to understand the different types available in the market. Coated aluminum laminate films are categorized based on their surface treatment and intended applications. The most common coatings include polyester, polyurethane, and PVDF (polyvinylidene fluoride), each offering distinct attributes. According to a 2022 market report by Smithers Pira, PVDF-coated films are favored for their durability and resistance to environmental factors, making them ideal for outdoor applications where longevity is critical.

Another consideration is the thickness of the film, which can vary significantly from 0.2mm to 1.5mm. Thicker films tend to provide better impact resistance and thermal insulation, but they may also come with a higher cost. A data analysis from MarketWatch highlights that the demand for thicker films has increased by 15% annually within the commercial construction sector as architects seek enhanced performance from facade materials. Conversely, polyester films, while lighter and more flexible, may not perform as well under extreme weather conditions, giving them limited applications.

In addition to coating types and thickness, surface finish options also play a pivotal role in aesthetic appeal and functionality. Matte and glossy finishes cater to different design preferences; glossy surfaces tend to reflect more light, enhancing luminosity in interior settings, while matte finishes offer a modern aesthetic with reduced glare. The choice ultimately depends on project requirements, ranging from high-traffic commercial areas to artistic installations, making it crucial to analyze specific material properties and expected performance to ensure the best fit.

| Type of Coating | Finish Type | Durability | UV Resistance | Application Areas | Cost (per sq. ft.) |

|---|---|---|---|---|---|

| Polyester Coating | Glossy | High | Moderate | Interior Signage | $1.50 |

| Polyurethane Coating | Matte | Very High | Excellent | Outdoor Displays | $2.00 |

| PVDF Coating | Satin | Ultra High | Superb | Architectural Applications | $3.50 |

| Epoxy Coating | Textured | Moderate | Low | Industrial Use | $1.20 |

| Powder Coating | Glossy/Satin | Very High | Good | Furniture, Architectural Elements | $2.50 |

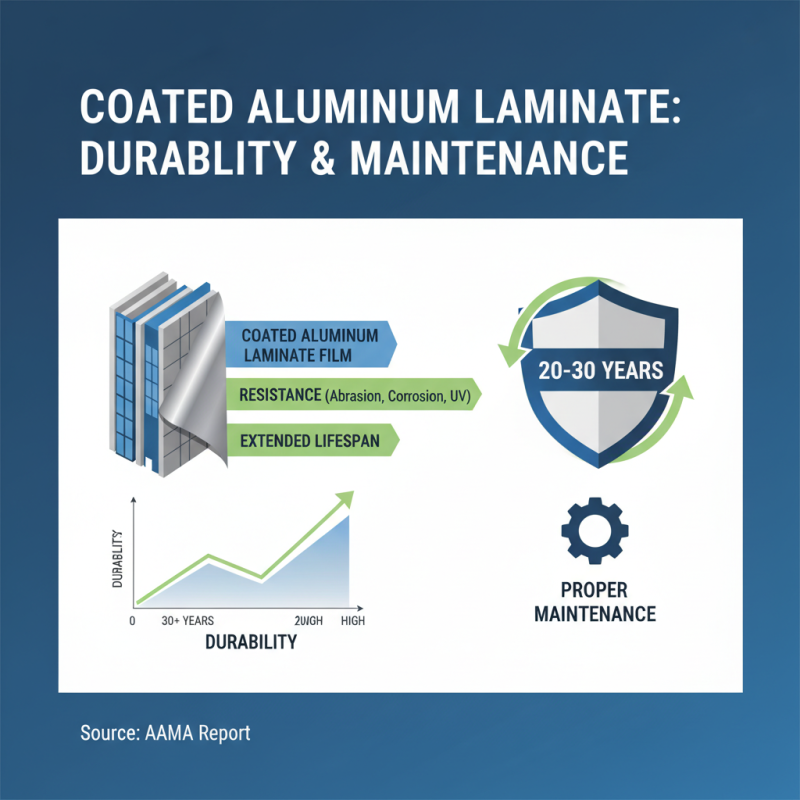

When selecting a coated aluminum laminate film for your project, understanding durability and maintenance needs is paramount. According to a report by the American Architectural Manufacturers Association (AAMA), coated aluminum materials can significantly enhance the lifespan of facade applications, with high-quality coatings providing resistance to abrasion, corrosion, and UV degradation. AAMA's studies indicate that exterior finishes can last between 20 to 30 years when properly maintained, making it crucial to choose a film that not only meets aesthetic requirements but also stands the test of time against environmental factors.

Maintenance considerations are equally important; the ease of cleaning and the frequency of upkeep can vary significantly between different coated films. A research paper published in the Journal of Coatings Technology and Research stated that films with self-cleaning properties can reduce maintenance efforts by up to 50%, as they repel dirt and contaminants. This reduces the need for chemical cleaners and minimizes labor costs associated with regular maintenance. Therefore, when opting for aluminum laminate films, it is advisable to assess their resistance to dirt accumulation and the recommended cleaning methods, which can have a lasting impact on both functionality and appearance over the project's lifetime.

When sourcing and purchasing coated aluminum laminate film for your project, consider the specific requirements of your application first. Different projects may necessitate varying thicknesses, finishes, and performance characteristics. Identify the environment in which the film will be used to ensure it can withstand the necessary conditions, such as UV exposure, moisture, and temperature fluctuations. This foundational understanding will guide you in selecting the right product that meets your needs.

One important tip is to evaluate multiple suppliers to compare quality and pricing. Request samples whenever possible, as this will give you firsthand experience with the texture, appearance, and durability of the film. Additionally, inquire about the film's specifications, such as its adhesive properties and any certifications it may have. This information can prove pivotal in making an informed decision and ensuring that the material aligns with industry standards.

Lastly, consider the supplier's reputation and customer service. A reliable supplier should be willing to address your queries, provide technical support, and offer guidance on the best practices for installation and maintenance. By focusing on these aspects, you can make a more confident purchase that enhances the quality and longevity of your project.