Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp+86 18621680941

Choosing the right Coated Aluminum Laminate Film for your project can significantly influence both the aesthetic and functional aspects of your final product. As noted by industry expert Dr. Lisa Reynolds, "The right selection of coated aluminum laminate film not only enhances the visual appeal but also ensures durability and longevity in application." This highlights the importance of making informed decisions when it comes to material selection.

In the rapidly evolving landscape of design and construction, the various properties and applications of coated aluminum laminate films are becoming increasingly critical. Whether you are considering these films for signage, architectural facades, or interior design elements, understanding their characteristics can help you achieve the best results. Factors such as thickness, finish, and resistance to environmental factors should be taken into account to select a film that meets the specific requirements of your project.

Taking the time to evaluate the options available in coated aluminum laminate films will empower you to create solutions that not only fulfill functional needs but also resonate with the intended audience aesthetically. With the right guidance and knowledge, you can ensure that your project stands out in both quality and design.

Coated aluminum laminate film is a versatile material frequently used across various industries for its unique properties and aesthetic appeal. This film consists of layers of aluminum and polymer, creating a robust and lightweight solution that is both durable and visually appealing. The coating can provide additional benefits, such as enhanced weather resistance, UV protection, and improved aesthetics, making it suitable for applications ranging from signage and architectural cladding to interior design elements.

In construction and architecture, coated aluminum laminate film is particularly favored for its excellent insulation properties and ability to withstand harsh environmental conditions. It is commonly used in facades due to its lightweight nature and the ease with which it can be shaped and installed. Additionally, its range of finishes allows designers to achieve a variety of looks, from metallic to matte, catering to different aesthetic preferences. In the automotive and packaging industries, this film is utilized for its moisture resistance and ease of cleaning, further broadening its scope of applicability. Understanding these characteristics can help you select the right coated aluminum laminate film that aligns with your specific project requirements.

When selecting the right coated aluminum laminate film for your project, several key factors should be taken into consideration to ensure optimal performance and durability. First and foremost, it’s essential to evaluate the specific application requirements. Whether the film is intended for interior decor, signage, or exterior façade, understanding its intended use will guide you in choosing the appropriate thickness, finish, and protective coatings that will withstand environmental impacts and wear over time.

Another crucial aspect is the aesthetic appeal of the laminate film. Consider the color options, surface textures, and reflectivity that suit your design vision. The visual characteristics of the film not only contribute to the overall aesthetic but can also affect the perception of quality and brand identity. Additionally, it's advisable to assess the compatibility of the coated aluminum laminate with adhesives and substrates, as well as its ease of installation. Thoroughly reviewing these factors will provide a clear pathway to selecting the ideal product that meets both functional and design criteria for your project.

| Factor | Description | Importance Level |

|---|---|---|

| Thickness | Choose a thickness that meets your durability needs. | High |

| Finish Type | Select a finish that matches your aesthetic requirements, such as matte or glossy. | Medium |

| Color Options | Consider the color range that complements your project design. | High |

| Environmental Resistance | Select films with resistance to UV rays, moisture, and chemicals if needed. | High |

| Application Method | Confirm the film is compatible with your application method (e.g., adhesive, heat seal). | Medium |

| Price | Evaluate your budget and select a film that offers the best value for your needs. | Medium |

When selecting coated aluminum laminate film for a project, evaluating the durability and performance of different options is essential. Durability is largely influenced by the type of coating applied to the aluminum. High-quality coatings can provide resistance to environmental factors such as moisture, UV radiation, and extreme temperatures. Therefore, it is crucial to examine the specific properties of each coating type—such as scratch resistance, corrosion resistance, and long-term stability—to ensure the film will withstand the intended application conditions.

Performance is another vital consideration, as it defines how well the coated aluminum laminate film will perform in real-world scenarios. Factors such as adhesion, flexibility, and tensile strength are paramount, particularly if the film will be exposed to significant stress or movement. Additionally, understanding how the coated surface interacts with inks or adhesives is critical for projects requiring printing or bonding. By assessing both durability and performance criteria, one can make an informed decision that aligns with the project’s requirements and anticipated lifespan, ensuring optimal results and cost-effectiveness.

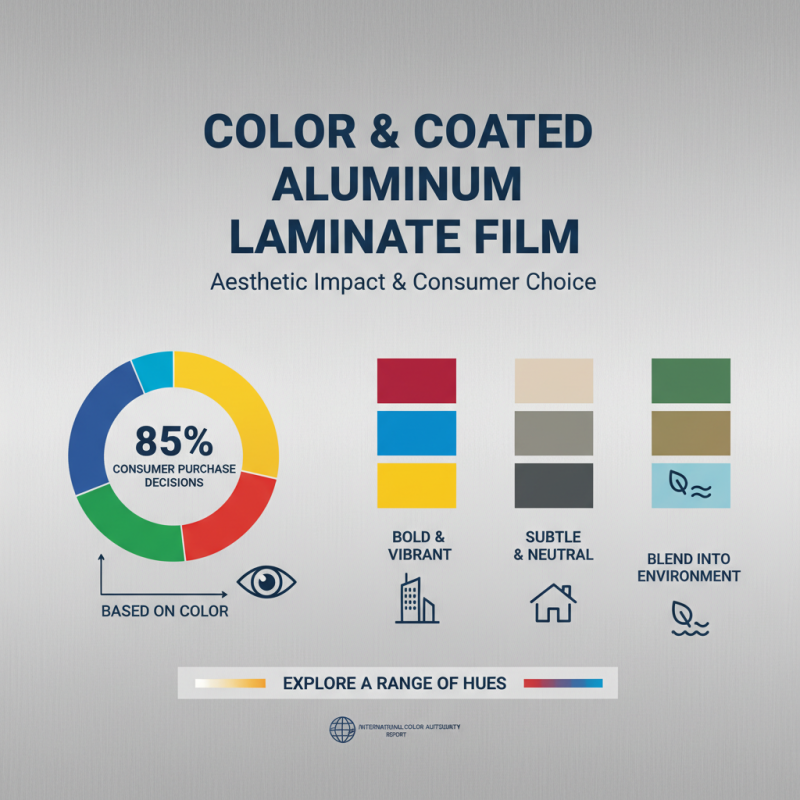

When selecting the right coated aluminum laminate film for your project, aesthetic options play a crucial role in achieving the desired visual impact. The color palette you choose can dramatically alter the ambiance of a space. According to a recent report by the International Color Authority, over 85% of consumers make purchase decisions based on color alone, underscoring the importance of selecting the right hues. When considering your project, it's essential to explore a range of color options, from bold and vibrant shades to subtle and neutral tones that can seamlessly blend into the environment.

In addition to color, the finish of the laminate film significantly contributes to its overall aesthetic. Finishes can vary from high gloss to matte, each offering distinct visual characteristics and practical implications. A report published by the Architectural Finishes Association indicates that high-gloss finishes not only enhance color saturation but also reflect light, making spaces appear larger and more inviting. Conversely, matte finishes can provide a sophisticated look while minimizing the appearance of fingerprints and smudges, which can be particularly important in high-traffic areas. By carefully analyzing these aesthetic options, you can ensure that your chosen coated aluminum laminate film complements your project's design and functional requirements.

When budgeting for coated aluminum laminate film solutions, it's essential to consider all aspects of the investment. Cost can vary widely depending on factors like thickness, finish, and even the specific applications you intend to use the laminate for. To ensure a comprehensive analysis, begin by evaluating the project requirements and desired specifications. This will help in obtaining accurate quotes tailored to your needs. Additionally, be mindful of potential hidden costs such as shipping, installation, or the need for specialized tools.

Tips: Before committing to a purchase, reach out to multiple suppliers to compare pricing and quality. Look for suppliers who provide transparent breakdowns of costs involved, which can help prevent unexpected expenses later on. Also, consider the long-term benefits of investing in higher-quality materials that may save money on maintenance and replacement in the future.

It's also wise to plan for contingency funds within your budget. Projects can hit unforeseen snags, leading to additional costs. Allocating a percentage of your budget for these emergencies ensures that you won’t be caught off-guard. Moreover, consider discussing financing options with suppliers or exploring bulk purchasing discounts, which may offer significant cost savings over time.