Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp+86 18621680941

In the rapidly evolving packaging industry, Coated Aluminum Laminate Film stands out. Experts like Dr. Emily Carter highlight its potential. She stated, "This material transforms how we think about product preservation." Utilizing Coated Aluminum Laminate Film can significantly enhance packaging solutions. Its properties allow for better barrier protection and durability.

Manufacturers face challenges when selecting materials. Some may overlook the benefits of using Coated Aluminum Laminate Film. It offers brightness, flexibility, and resistance to moisture. However, not all companies fully understand its advantages. This leads to missed opportunities in product presentation and shelf life.

A successful application of Coated Aluminum Laminate Film can showcase a product effectively. Attention to detail in design is crucial for maximizing impact. Also, companies need to reflect on how they implement such materials. Knowledge growth in this area can lead to innovative packaging solutions that meet market demands. Embracing this technology could redefine product packaging on many levels.

Coated aluminum laminate film is increasingly popular in the packaging industry. Its unique properties offer effective solutions for various applications. This film provides excellent barrier protection against moisture and oxygen. This ensures longer shelf life for packaged products. Food items, pharmaceuticals, and cosmetics particularly benefit from this feature.

Understanding its versatility is crucial. The film can be customized in thickness, finish, and color, making it suitable for different packaging needs. However, achieving the perfect balance between aesthetics and functionality can be challenging. Sometimes, businesses may prioritize appearance over durability, leading to packaging failures. It is important to always test the material under real conditions.

While coated aluminum laminate film offers many advantages, it also presents challenges. Environmental concerns about disposal are significant. Many consumers are demanding more sustainable options. Companies must reflect on their choices. Investing in recyclable or biodegradable materials could be a path forward. Finding the right approach is not always easy, and there’s room for growth and improvement in this area.

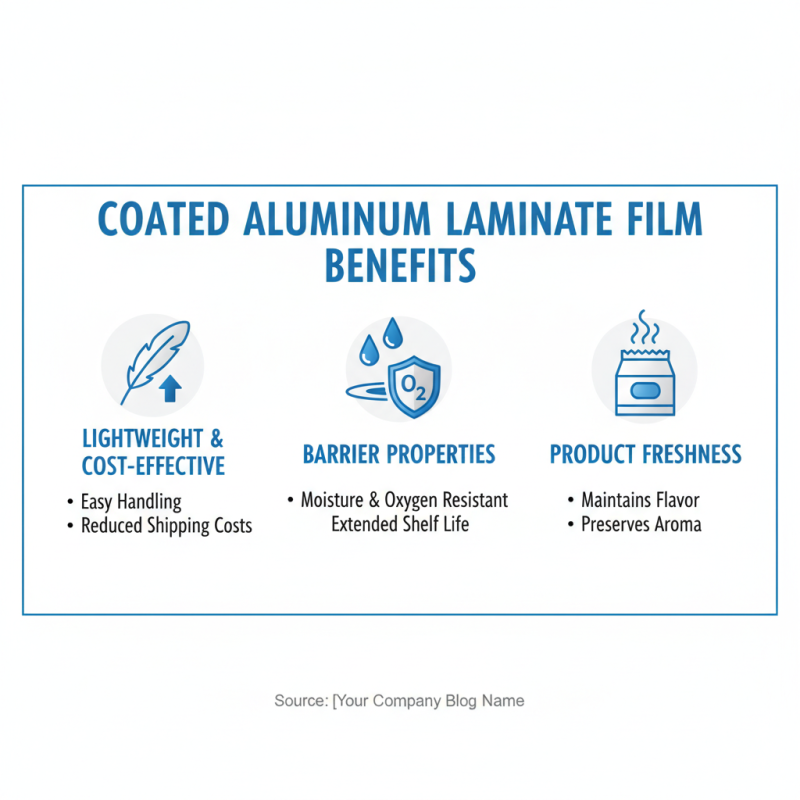

Coated aluminum laminate film offers numerous benefits for packaging solutions. Its lightweight nature makes it easy to handle. Unlike heavier materials, it reduces shipping costs. This film is also resistant to moisture and oxygen, ensuring product freshness. Many companies appreciate this quality. It helps maintain flavor and aroma.

The visual appeal of coated aluminum laminate film is another advantage. Products wrapped in this film look sleek and professional. This can attract consumers’ attention. However, not all designs utilize the film’s full potential. Limited colors or patterns may not stand out on shelves. Brands should explore creative designs to maximize impact.

Durability is a crucial factor. Coated aluminum laminate film withstands various environmental conditions. Yet, some users may overlook proper sealing methods. Inadequate sealing can lead to package failure. It is essential to ensure all edges are secure. Monitoring the production process can help identify issues. Adjustments may be needed to improve performance.

Coated aluminum laminate film is revolutionizing packaging solutions. This material offers a lightweight yet durable option that enhances product protection. Its unique structure includes a thin layer of aluminum, providing excellent barrier properties. These barriers protect against moisture, light, and air, which can compromise product quality.

The technical specifications of coated aluminum films reveal impressive performance metrics. For instance, the thickness can be controlled to meet specific needs. Some films can be as thin as 0.2 millimeters while still holding up well against external factors. Additionally, the flexibility of this material allows it to adapt to various shapes and sizes, a practical aspect for many businesses.

However, challenges remain, especially in environmental impact. While the films are effective, their recyclability is a concern. Many facilities struggle to process aluminum laminates properly. This raises questions about sustainability in packaging decisions. It might be worthwhile to rethink how coated aluminum films are utilized in the future. Finding a balance between performance and environmental responsibility is crucial. This ongoing dialogue can lead to innovative packaging solutions that align with both product integrity and ecological awareness.

Coated aluminum laminate film is gaining traction in various industries for its versatile applications. In the food packaging sector, this film offers excellent barrier properties against moisture and oxygen. It ensures longer shelf life for perishable goods, such as snacks and dairy products. Moreover, it can also maintain freshness, which is crucial for consumer satisfaction.

In the pharmaceutical industry, this film provides protection for medications against environmental factors. It helps in keeping the integrity of sensitive compounds. However, some challenges exist. The film can be difficult to seal properly in high-speed processes. Operators must pay close attention to machine settings. This problem can lead to compromised packaging quality.

Cosmetics also benefit from coated aluminum laminate film. The film can enhance product appeal with eye-catching designs. It protects products from light exposure, crucial for skincare items. Yet, achieving perfect aesthetics on the film surface can be tricky. Bubbles or imperfections may occur, requiring a careful review of production practices. Overall, industries must remain mindful of these challenges while harnessing this innovative material.

Coated aluminum laminate film is gaining traction in packaging due to its sustainability. Industry reports indicate that aluminum can be recycled indefinitely, saving over 90% of the energy needed for new production. This is a compelling feature, as around 75% of all aluminum produced is still in use today.

However, the environmental impact of coated aluminum packaging is not entirely positive. While recycling rates are high, the initial production process involves significant emissions. Some studies indicate that aluminum production contributes to nearly 2% of global carbon emissions. Additionally, the coatings used can complicate recycling processes.

Transparency in packaging is crucial. Consumers increasingly demand information about the source and lifecycle of materials. A survey revealed that 70% of people prefer brands that are environmentally responsible. Packaging solutions must evolve alongside these expectations. The challenge lies in balancing effective packaging with genuine sustainability efforts. This ongoing debate continues to shape industry practices and consumer choices.