Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp+86 18621680941

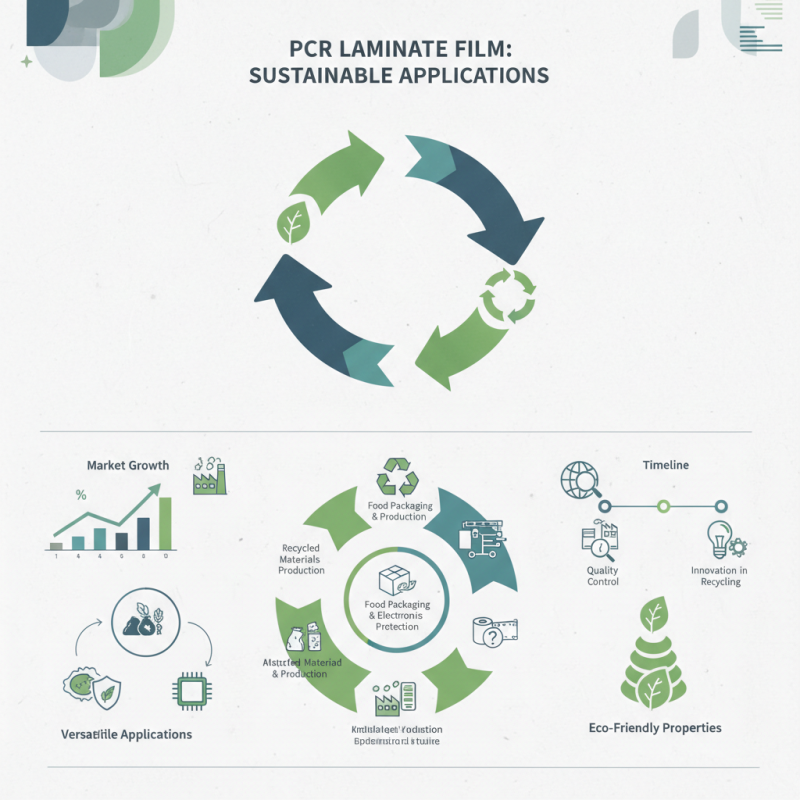

Pcr Laminate Film is gaining traction in various industries due to its versatility. According to a recent market report, the global demand for laminate films is projected to grow at a CAGR of 4.5% through 2025. Pcr Laminate Film stands out thanks to its eco-friendly properties. It is made from recycled materials, reducing landfill waste significantly.

Moreover, the application of Pcr Laminate Film spans from food packaging to electronics. For food products, its barrier properties effectively extend shelf life, a crucial feature for consumer satisfaction. In electronics, this film protects sensitive components from moisture and dust. However, the quality of Pcr Laminate Film can vary among manufacturers, leading to inconsistent performance.

Despite its benefits, the industry faces challenges. The recycling process for Pcr Laminate Film remains complex and not yet widely adopted. Companies must evaluate their supply chains critically. It's essential to ensure that sourcing practices align with sustainability goals. As demand grows, the need for innovation in production and recycling methods becomes evident.

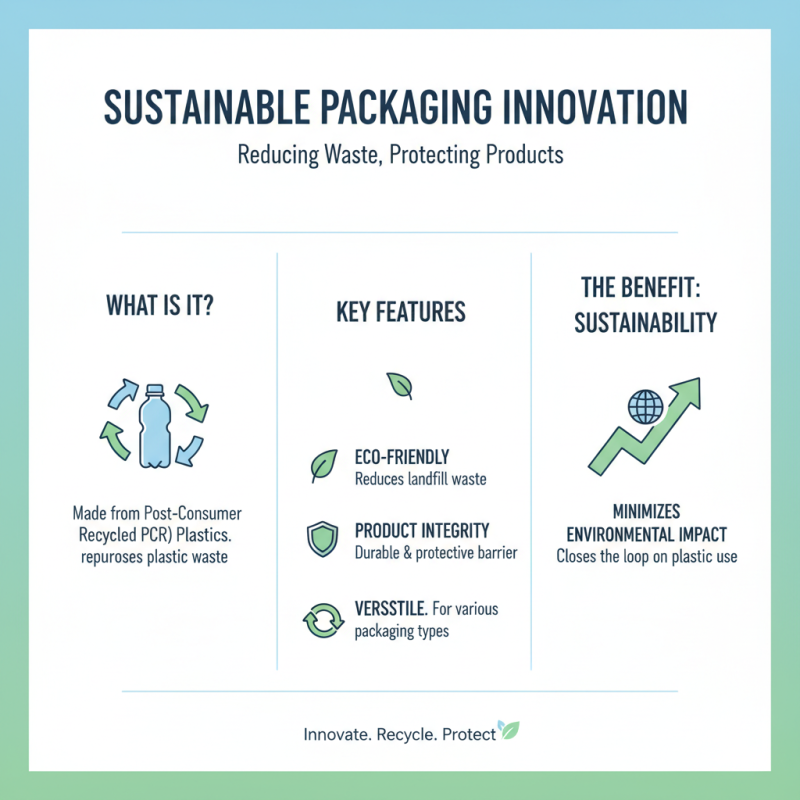

PCR laminate film is an innovative material used in packaging. It is made from post-consumer recycled (PCR) plastics, which helps reduce waste. The definition of PCR laminate film revolves around its key feature: sustainability. This film is designed to be environmentally friendly while maintaining product integrity.

The composition of PCR laminate film typically includes layers of recycled plastic materials. These layers might combine different polymers to enhance durability and barrier properties. When manufactured, this film can be both lightweight and strong. It supports various packaging needs, from food to non-food items. However, achieving the perfect balance of sustainability and performance can be challenging. Sometimes, the film may not meet all desired specifications.

PCR laminate film represents a step towards a circular economy. Its use contributes to reducing dependence on virgin plastics. However, the quality can vary based on the source of recycled materials. This inconsistency needs further investigation and improvement. Manufacturers must continuously refine processes to enhance the quality of PCR laminate films. These challenges highlight the ongoing need for innovation in sustainable materials.

PCR laminate film plays a significant role in the packaging industry. Its use significantly reduces plastic waste. According to a recent report by Smithers Pira, the global sustainable packaging market is expected to reach $500 billion by 2027. This trend highlights the importance of eco-friendly solutions like PCR films.

In food packaging, PCR laminate films are increasingly popular. They offer excellent barrier properties, extending shelf life. The average shelf life of food products can increase by 20% with proper packaging. Moreover, brands are shifting towards sustainability. A survey from the Sustainable Packaging Coalition found that 74% of consumers prefer products with recyclable packaging. This consumer preference drives companies to adopt PCR technology.

Despite these benefits, challenges remain. Not all PCR films perform well under various conditions. Quality control is essential to ensure durability and safety. Brands must balance sustainability with performance. This balance is often difficult to achieve. The need for further innovation is clear as the market grows. Continuous improvement is essential in this evolving landscape.

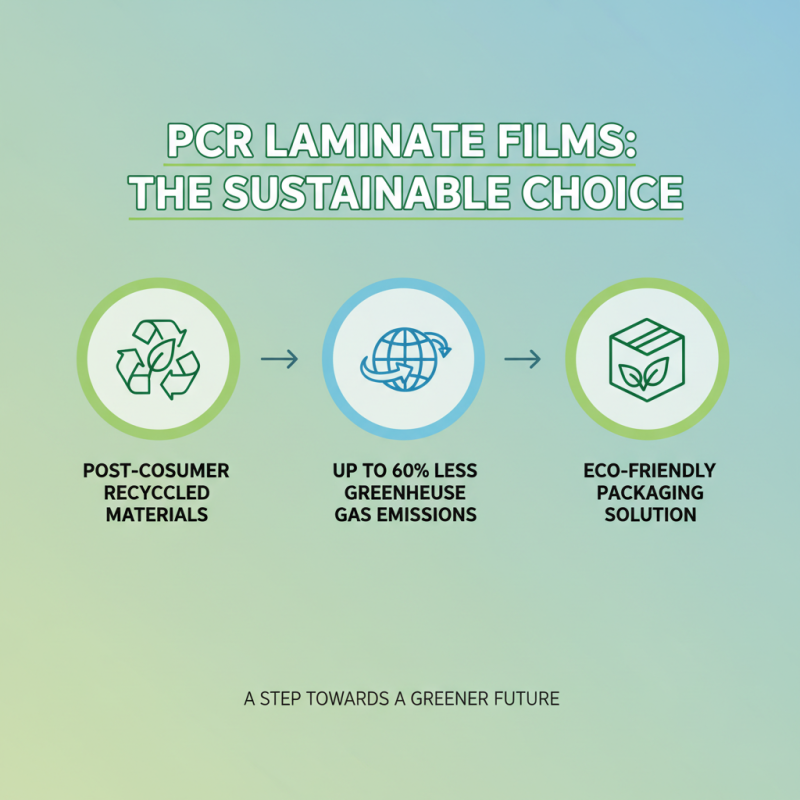

PCR laminate films offer a compelling alternative to traditional plastics. These films are made from post-consumer recycled materials, enhancing their sustainability. Reports indicate that using PCR materials can reduce greenhouse gas emissions by up to 60% compared to virgin plastics. This significant impact makes PCR laminate films a step towards eco-friendly packaging solutions.

The performance of PCR laminate films is noteworthy. They maintain similar durability and flexibility as conventional plastics. A study from the Flexible Packaging Association suggests that nearly 70% of consumers prefer products packaged in environmentally friendly materials. However, not all industries adopt these innovations. The transition can be slow in some sectors due to cost concerns.

Challenges in sourcing high-quality PCR materials still exist. The recycling process can complicate production, leading to variability. This inconsistency may result in performance issues. As demand grows, investments in technology to enhance quality control are necessary. The benefits of PCR laminate films are clear, but consumers and manufacturers must confront these hurdles together.

PCR laminate film is increasingly popular due to its eco-friendly attributes. The manufacturing process plays a crucial role in its effectiveness. This process typically begins with collecting post-consumer recycled (PCR) plastics. These plastics are cleaned and processed, transforming them into a usable resin.

During the film production, the extruding process is essential. Melted resin is formed into thin layers, which are then cast or blown into films. According to industry reports, advancements in technology have improved film clarity and strength, thus meeting modern packaging demands. More than 30% of the PCR laminate film in use today features enhanced barrier properties, making it suitable for various applications.

Tips: Always ensure that the PCR materials are sourced responsibly. High-quality inputs lead to a better finished product. Never underestimate the importance of quality control during production. Small errors in the process can lead to significant issues in performance.

The market for PCR laminate films is projected to grow. However, not all manufacturers adhere to strict sustainability guidelines. It’s vital to question the sources of PCR materials to support truly eco-friendly practices. A commitment to transparency can encourage better choices in the industry.

| Property | Description | Application |

|---|---|---|

| Material Composition | Made from recycled plastics, primarily PET and PE. | Used in packaging solutions to reduce environmental impact. |

| Thickness | Typically ranges from 50 to 200 microns. | Suitable for food packaging, electronic goods, and consumer products. |

| Sealing Method | Heat sealing and adhesive bonding. | Ensures product freshness and shelf life stability. |

| Sustainability | Reduces the reliance on virgin plastic materials. | Contributes to global recycling efforts and sustainability initiatives. |

| Performance | Excellent barrier properties against moisture, gases, and aromas. | Ideal for maintaining the quality of food products. |

PCR laminate film technology is evolving rapidly. This innovation focuses on using post-consumer recycled materials for packaging. The goal is to reduce waste and promote sustainability. Consumers are becoming more conscious about their environmental impact. Brands must keep up with these changes.

One exciting trend is the improvement in film durability. Advanced processes enhance the performance of PCR laminate films. This makes them suitable for various applications, including food packaging and cosmetics. However, some challenges remain. Not all recycled materials offer the same quality. This inconsistency can affect the final product.

Another area of advancement is customization. Brands are looking for unique designs that connect with their audience. PCR laminate film allows for creativity while maintaining eco-friendliness. The industry continues to push for better recycling processes. Still, there is work to be done. Often, the recycling rates for these materials are not sufficient. This gap highlights the need for awareness and improved practices in waste management.