Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp+86 18621680941

Choosing the right laminate tube can be a daunting task. With so many options available, it’s important to make informed decisions. Steve Williams, a packaging expert, once said, "The right laminate tube can enhance product appeal significantly." This highlights the need for careful consideration.

When assessing laminate tubes, think about your product's requirements. Different materials offer various benefits. For example, some are better for protecting contents from light and air. Choose wisely based on your specific needs.

It’s also essential to consider aesthetics. A visually appealing tube can capture consumer attention. However, functionality should not be sacrificed for looks. Finding balance is key. Explore options, but remember: not all choices will fit your product perfectly. Reflect on what matters most.

When selecting laminate tubes, the material choice plays a crucial role in their functionality. Different materials offer various benefits, impacting durability, barrier properties, and aesthetic appeal. Polyethylene is common for its flexibility and moisture resistance. Alternatively, polypropylene provides a more rigid structure. Each option has distinct characteristics worth considering.

A good understanding of these materials helps in making informed decisions. For instance, a clearer tube might enhance product visibility. It also allows consumers to see what they are buying. However, this choice can sometimes compromise strength. Reflecting on these trade-offs is essential. You may need to balance visibility with protection depending on the product inside.

Comfort with selections often comes through experience. In some cases, inadequate research leads to poor choices. Many overlook critical factors like temperature sensitivity or chemical compatibility. These oversights can result in product failure. A thoughtful approach to material selection ensures that laminate tubes meet both functional and aesthetic needs, setting the foundation for success.

When selecting a laminate tube, thickness and durability are critical factors. A thicker tube often provides more protection for the contents inside. However, this can mean added weight and cost. Consider what you need to protect. Delicate products may require more robust protection. A tube that's too thin may not withstand transport.

Durability comes from the materials used. Different laminate compositions can influence how well a tube resists punctures and tears. Conduct a simple test. Squeeze different samples to feel their resilience. Some may feel flimsy, while others are surprisingly strong. A balance is vital. A perfectly durable tube might not always equate to the best choice for specific products.

Environmental conditions must also be considered. Humidity and temperature changes can affect tube performance. Will your product face varying climates? This factor may require a rethink of your initial choices. It's best to revisit your needs regularly. Ask questions, reassess, and stay informed about new materials in the market. The perfect laminate tube should evolve with your product requirements.

When selecting laminate tubes, evaluating their barrier properties is crucial. These tubes often contain sensitive products like cosmetics and pharmaceuticals. According to a report by Smithers Pira, 60% of product failures in these sectors relate to inadequate packaging. This highlights the importance of reliable barrier technologies.

Different materials offer varying levels of protection against oxygen, moisture, and UV light. For instance, a multilayer structure can significantly enhance barrier integrity. It’s essential to analyze each layer's composition and performance. Yet, many manufacturers overlook the specific needs of their products. A one-size-fits-all approach can lead to compromised integrity and spoilage.

Furthermore, the testing methods for barrier properties should not be underestimated. Standard tests like permeability measurement provide insight but may not capture real-world conditions. Different temperatures and humidity levels can affect the tubes' performance. Be cautious of relying solely on lab results. Industrial applications may reveal weaknesses not seen in controlled environments. Regular evaluations and adjustments are necessary to maintain product quality.

| Property | Best Range | Impact on Product Integrity |

|---|---|---|

| Oxygen Barrier | < 1 cc/m²/24h | Prevents oxidation and prolongs shelf life |

| Moisture Barrier | < 0.1 g/m²/24h | Maintains product consistency and prevents spoilage |

| Light Barrier | Opaque or UV-filtering | Protects sensitive ingredients from degradation |

| Chemical Resistance | High resistance | Ensures integrity of contents against reactive substances |

| Puncture Resistance | Strong and durable | Reduces risk of leaks or contamination |

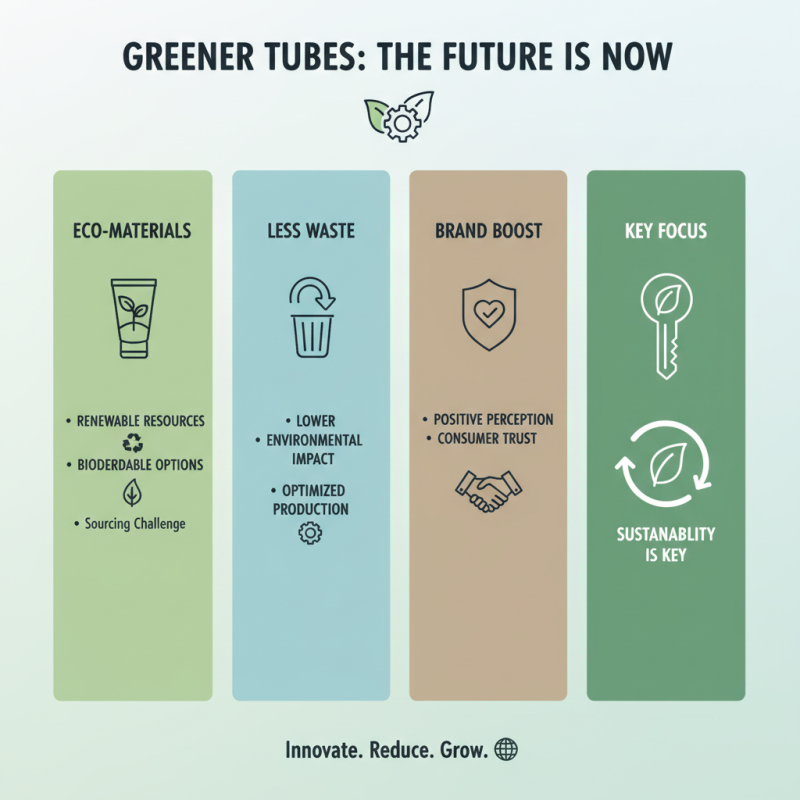

Sustainability is key in laminate tube manufacturing. More brands are focusing on eco-friendly materials. Consider using renewable resources. This not only reduces waste but also enhances your brand image. Biodegradable options are gaining popularity, but they can be harder to source.

Recycling is another critical aspect. The production process must allow for easy recycling of materials. Consumers are increasingly demanding products that are easy to recycle. This can complicate the design process. Finding the right balance is essential. Some manufacturers might compromise on durability to make their tubes recyclable.

Life cycle assessment is useful in evaluating sustainability. It provides insight into environmental impacts throughout a product's life. However, such assessments can be challenging to implement. Data availability and accuracy might restrict decision-making. Transparency is vital, but many brands fall short in this area. Engaging with suppliers who prioritize sustainability can make a difference. Yet, this relationship requires ongoing effort and communication.

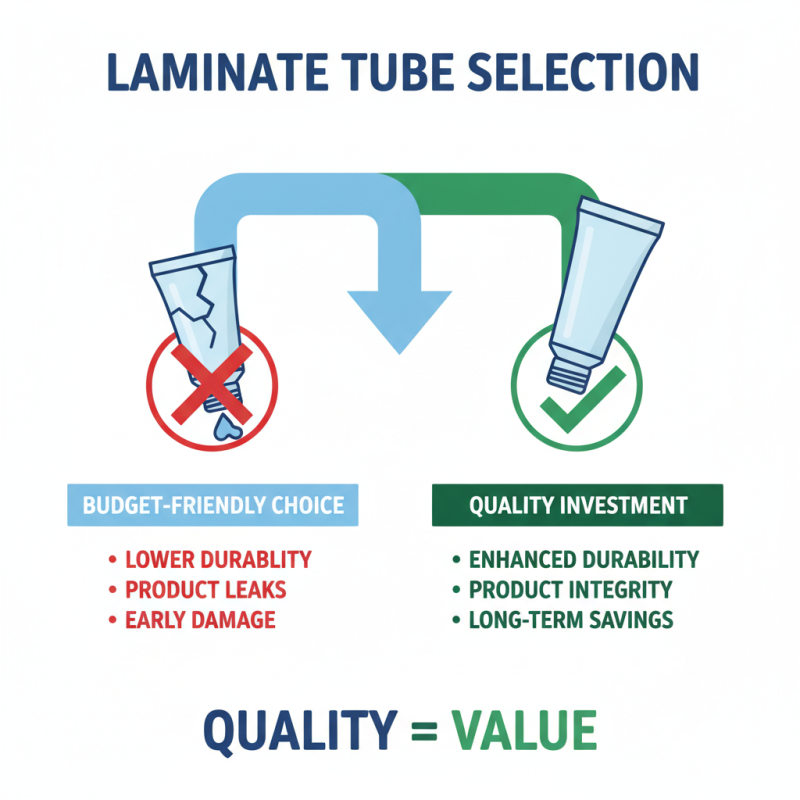

When selecting a laminate tube, cost plays a crucial role. A budget-friendly choice often compromises quality. You might save money upfront but face issues later. For instance, low-cost tubes may be less durable. This could lead to product leaks or early damage. So, investing in quality is essential.

Analyzing costs involves more than just the purchase price. Consider production rates and longevity. Cheaper options may require frequent replacements. This adds to overall costs over time. Look for suppliers that offer a balance of quality and price. Researching features can also help. A robust laminate tube often pays off in reliability. It’s worth taking the time to compare different options.

Reflecting on your choices can minimize regrets. Ask yourself: Are the savings worth it? Sometimes, opting for a slightly higher initial investment can yield better long-term results. Be cautious of deals that seem too good to be true. A thorough cost analysis ensures that you’re not sacrificing quality for a lower price. Balancing your budget with quality needs careful consideration.